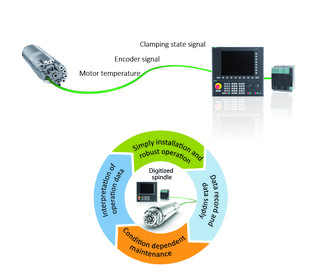

| Dashboard displays the information on the master data of the connected main spindle | | Time-efficient access to required information in case of maintenance or service |

Statistics for operating points:

speed / torque / temperature | | Information on possible power reserves and suitability of the design |

| Statistics on tool clamping times | | Evaluation of the clamping times in comparison to the reference value |

| Statistics on the clamping condition | | Detection of wear of the clamping system through change of the clamping times

|

| Selection and comparison of statistical data at different points in time | | Recognition of changes in use

|

| Export of saved data in a standard CSV format | | Management and monitoring of globally distributed machine parks |

| | | New service methods and business models |